Today’s challenge

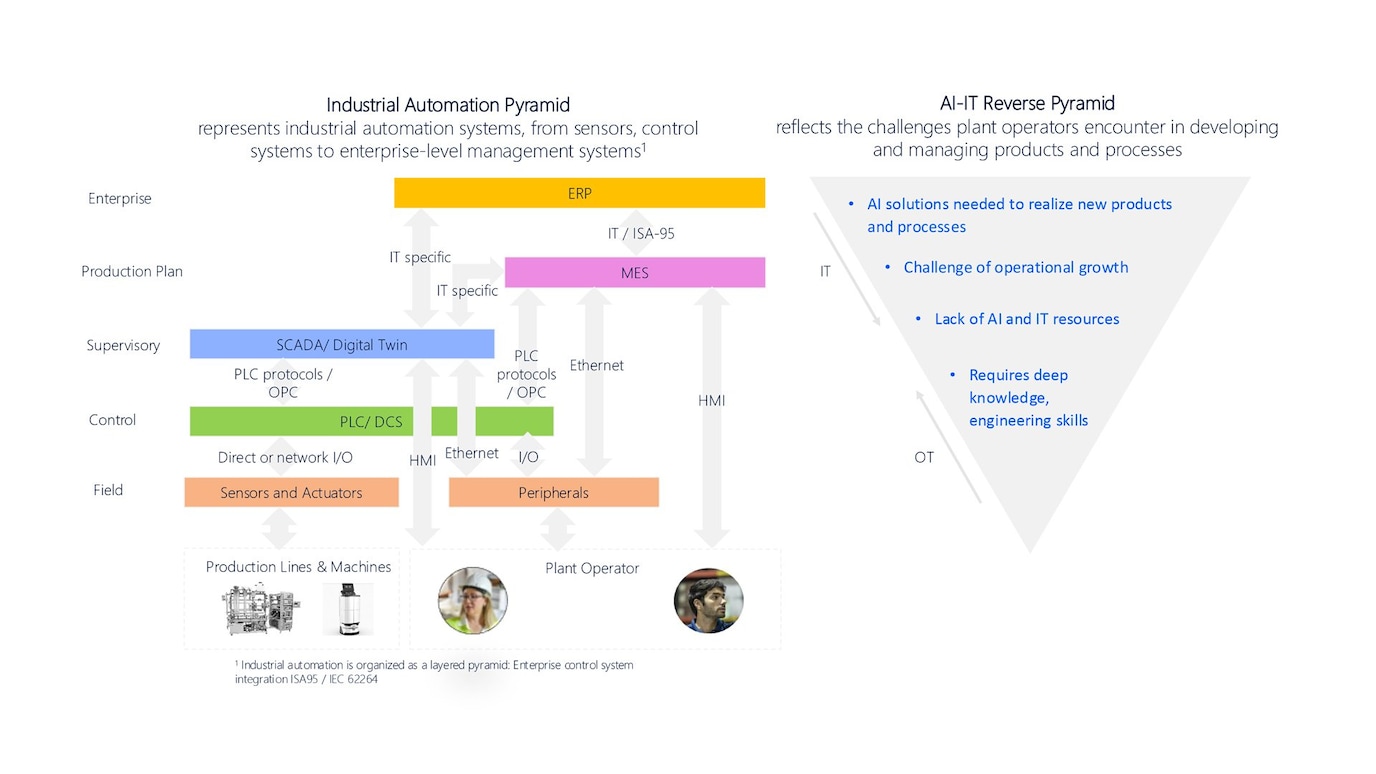

Today, the digitalization of industrial plant operations involves far more than just automation systems. Plant managers oversee processes within an industrial automation environment that integrates a variety of systems, including production machinery, programmable logic controllers (PLC/DCS), supervisory control and data acquisition (SCADA), digital twins, manufacturing execution systems (MES), and enterprise resource planning (ERP) systems.

Our solution

Plant operators are facing the challenge of managing the growth in operations and the lack of available engineering resources to create the automation solutions they need across all these systems. Without this in-depth expertise and domain-specific knowledge, new products and processes are difficult to realize.

While new products and process creation require deep knowledge and engineering skills at all industrial automation layers, the AI-IT Reverse Pyramid reflects the areas where AI solutions can have the greatest impact. The higher impact of AI is expected to be found towards the top part of the industrial automation pyramid.

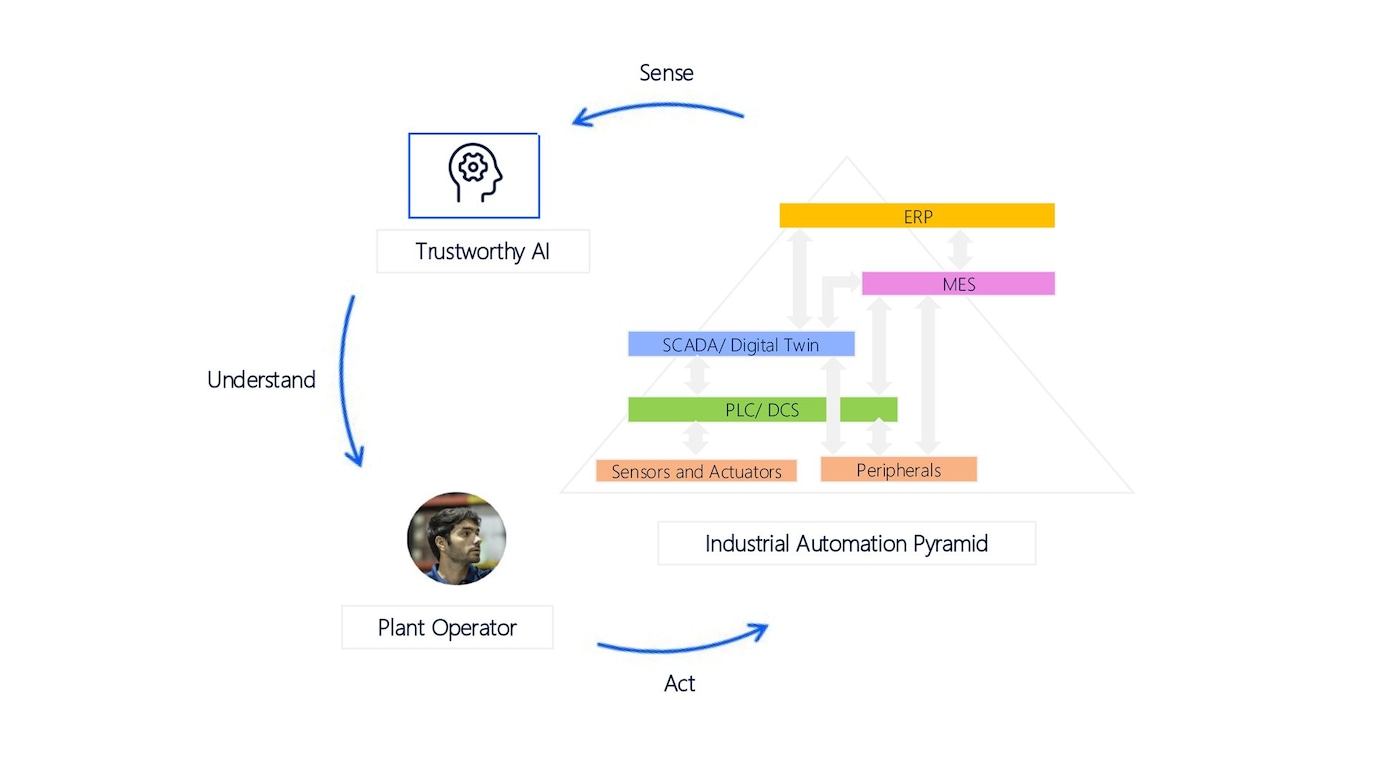

We aim to simplify the way plant managers can monitor and operate their processes using Bell Labs’ trustworthy AI technology.

With our trustworthy AI technology, plant managers can get the right monitoring and process optimizations in place to boost productivity and efficiency; and increase quality.

Key technology enablers

We create trustworthy AI systems that reliably extract insights from OT data and create automations that are easy for humans to understand. Plant operators can use our AI systems to sense, understand, and act on the OT environment.

Please complete the form below.

The form is loading, please wait...

Thank you. We have received your inquiry. Please continue browsing.