The future of North American manufacturing is digitally driven

Global and national pressures facing North America’s manufacturers are driving an evolution in how they do business. Factories, machines and workers continue to produce goods using existing processes, but to achieve the flexibility, resilience and sustainability essential to meeting today’s challenges, manufacturers must turn to digital solutions.

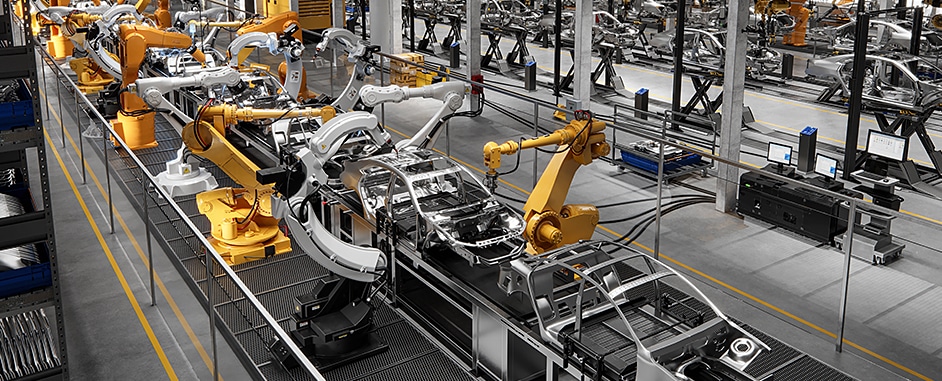

Enabling this evolution are Industry 4.0 driven technologies and applications that can make manufacturing more agile, efficient and hyper-productive. Taking advantage of them will require transforming the foundational networks within manufacturing facilities — to support the robotics, sensors and advanced automation applications of Industry 4.0 — while at the same time ensuring reliable and secure connectivity to the cloud and corporate hubs.

Most of all, this digitalization journey will require that manufacturers be flexible in adopting new business models, new approaches and looking beyond their traditional technology view.

Today’s challenges need tomorrow’s solutions – now.

The advent of highly “cost-optimized” single-source, off-shore manufacturing created massive disruptions in the supply chain when faced with the challenges of the COVID-19 pandemic, and other recent climate-fueled environmental events over the last few years. It seems either one or another necessary ingredient to our daily lives is “missing” from the shelf on a fairly regular basis, and it will continue to be a challenge as geopolitical unrest and climate events continue to intensify.

In resilient, high-performance communication networks, when one channel is disrupted, the system of redundancy ensures another channel instantly and seamlessly picks up and takes over. Manufacturers are looking for ways to add resilience, agility and adaptability to their supply chains and manufacturing operations so that external events can be managed minimizing their impact on productivity. But – it’s not just for resilience against uncontrollable events, it is also an opportunity to develop new ways to manufacture and bring lucrative business benefits to their operating models.

One strategy manufacturers are exploring is nearshoring. Nearshoring brings manufacturing operations closer to the customer, target market or location where the product is needed. Maximizing the benefits of this strategy requires embracing Industry 4.0 and bringing, smaller, strategically located, digitally enabled, highly automated factories online, and connecting them to the broader corporate operation for the seamless flow of operational data and intelligence. The highly automated nature of nearshoring operations also allows a manufacturer to use fewer manual processes, enabling these plants to be located anywhere, and operated by fewer, yet highly skilled technical labor who represent the new era of factory labor.

A glimpse into the future

To overcome these challenges — and thrive while doing it — manufacturers can embrace the latest industrial revolution by transforming their processes, procedures and facilities to realize new levels of efficiency and attract the next-generation augmented workforce. Critically, this will require strong, high-performance, low-latency networks that offer the stability and security to safeguard data while maintaining always-on reliability.

At Nokia, we’ve coupled our expertise in private wireless and edge cloud networks with a robust ecosystem built with leading industrial technology partners - bringing substantial business benefits and innovative use cases to manufacturers throughout North America – and the globe. With the right foundation built on highly reliable, high-performance industrial communication networks, Industry 4.0 technologies can allow manufacturers to:

- Connect rugged industrial devices and machines to communicate and collaborate faster and better under any condition while enhancing operational performance.

- Analyze data from sensors and localized compute capabilities to get visibility into equipment and labor effectiveness and accurately simulate manufacturing conditions.

- Create digital twins using powerful computing to simulate new products and services — without the need to re-configure factories to produce prototypes.

- Optimize their operations with private wireless, 4G/5G, and WiFi6 to improve factory automation, performance, safety, and flexibility - enabling quick adaptations to meet to changing market conditions.

These use cases and more will be featured by Nokia and our partners at this year’s IMTS/Hannover Messe USA exhibition and conference in Chicago.

The power of partnership

Just as the network is critical for Industry 4.0, so is partnership. The right partner with the right expertise can develop not only technologies but the ecosystem to support your Industry 4.0 journey.

This year’s Hannover Messe USA is a unique opportunity to see the developments on the road to Industry 4.0 realization. We’re looking forward to sharing with the North American manufacturing market the technologies we’ve developed together with our partners. Stop by our Nokia booth and see how we can help this critical market evolve and transform their business for the future.

Learn more about we’re helping manufacturers realize their Industry 4.0 ambitions.