Circularity and geodiversity

Circularity

At Nokia, we look at circularity from two perspectives. First, how we can increase the usage of non-virgin materials in the creation of new products and packaging. Second, how we can ensure maximum circularity of our operational value chain. This means that we embed circularity into everything we do.

Efficiency, the optimized use of resources and digitalization are key contributors to increase circularity. Traditional ownership of goods is changing to access to services and to the use of digital platforms for a sharing economy, all of which can improve circularity.

Our strategy to increase operational circularity follows the classic waste hierarchy. The first principle of the hierarchy is always the avoidance of waste, which we do through digitalization, operational efficiency and product life extension. As we are not able to dematerialize everything, good waste management practices are important as well.

We have set targets to increase the use of circular materials in new products. We introduced a circular metric to guide our operational circularity journey and to close the material loop. Our target is to be 95% circular with regard to waste in 2030. This target includes waste across our value chain: from our own top 20 sites based on waste production, including our own final assembly factories, supply chain final assembly factories, installation projects at customer sites, and product takeback.

The purpose of the new target is to improve waste management so that disposal to landfill is minimized and the waste produced will be either reused, recycled or recovered. To reach our target we aim to improve our waste-related data management and work with stakeholders to help ensure the best possible circular solutions for obsolete materials across geographies.

In 2023 we achieved a circular waste level of 86% with the data coverage we had in 2023. We have recognized areas where high circularity rate has already been achieved and also areas requiring further action. There are still data gaps to be closed but data accuracy has increased. Annual waste circularity outcome for 2023 was 86%.

At Nokia we look at circularity from two perspectives

We continue to progress with the creation of ICT-specific circular economy standards with the International Telecommunication Union (ITU) and the European Telecommunications Standards Institute (ETSI), providing a common industry view on circularity and sharing best practices.

In 2023 an assessment method for circularity-performance scoring (ITU-T L.1023) was revised and published, making it applicable for a much wider product set including network infrastructure ICT goods, while the earlier standard was mostly tailored toward consumer electronics. New criteria and requirements related to robustness, material recycling compatibility, recycled metal content and other aspects related to package recycling and recyclability were also added. Work is ongoing on a global digital sustainable product passport, a model for product information on sustainability and circular economy, and other work items related to e-waste management and circular economy.

For over 30 years, we have had well-established circular practices that utilize the full value of our products. We take back or acquire excess and obsolete products from customers and markets, and then refurbish, repair or remanufacture these units for inclusion in the product supply chain for customer purchase or our own internal use. As an original equipment manufacturer, we maintain processes that keep products at their highest value and quality for multiple uses and for the longest time possible through our global services.

Circular products and services portfolio

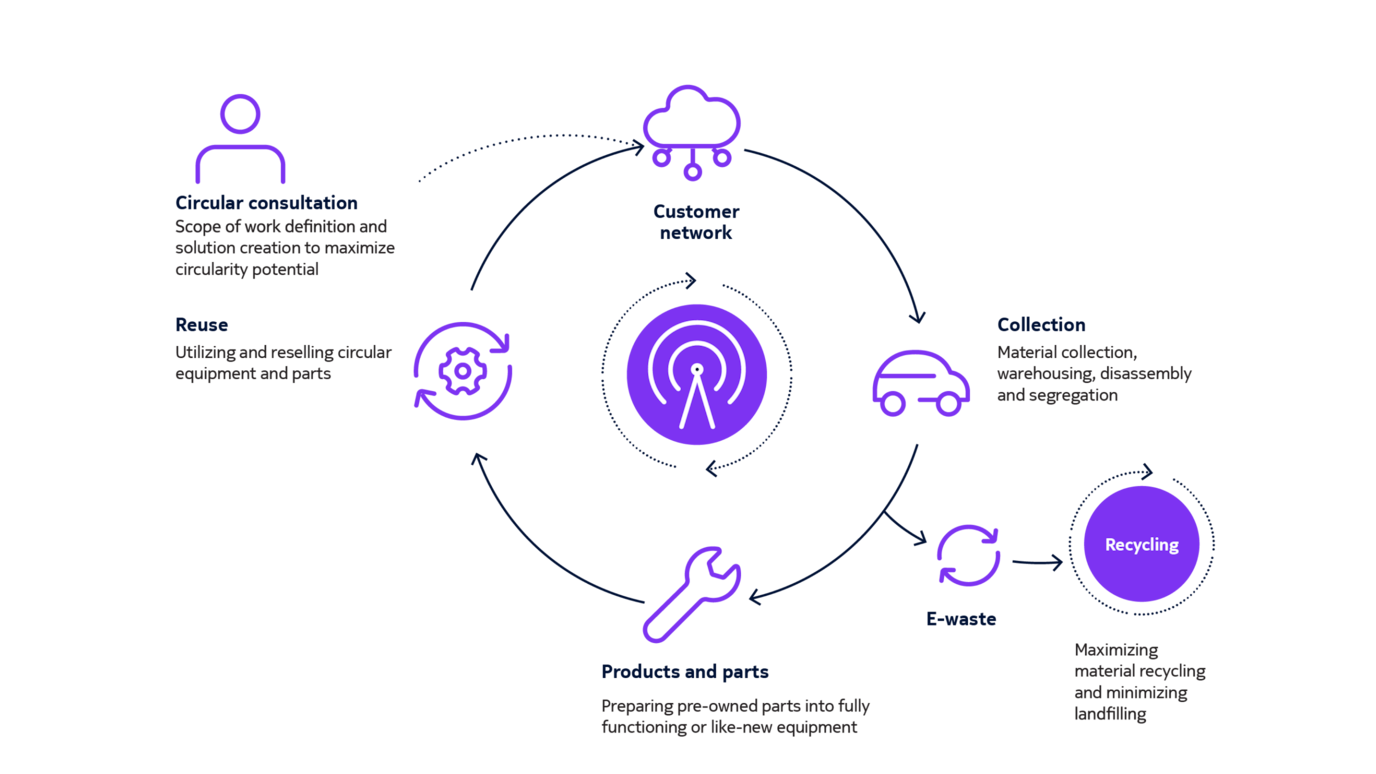

At Nokia, we are focused on strengthening the circularity of our customer offering. Our Circular Products and Services portfolio enables customers to shift more quickly into the circular economy and ensures that the customer network evolution is sustainable. We take on the collecting, refurbishing, reusing, reselling and recycling of telecom equipment during network upgrades or expansions.

Nokia Circular products and services consists of four modules that can be customized to meet e2e customer requirements:

- Asset Recovery: Reacquiring (takeback/buyback) and handling customer dismantled surplus products, including consultation, logistics and project management

- Circular Products and Parts: Selling circular products and parts to operators looking to expand their network using circular products

- Refurbishment Service: Extending hardware lifetime but also testing and validating customer-owned dismantled product equipment for reuse in the network

- Recycling Service: Maximizing material recycling and minimizing landfill, and e-waste management

For further information on how we do this you can read more on the Circular products and services webpage.

Circular products and services

Ensure that your network evolution is sustainable.

Recycled content in products

In 2023, we continued our work to increase the use of recycled material content in our products. First, we worked further with our suppliers of cast aluminum parts to fully understand raw material acquisition practices and the potential to increase the recycled content in our components.

We estimate that 43% of over 10,000 tons of cast aluminum parts used in Nokia products in 2023 have recycled content in them. The recycled material used in our products today is mainly from inter-industry manufacturing waste, as there are still challenges related to material purity, availability of recycled materials and verification of source of materials. We see positive developments from suppliers of aluminum – in terms of actively searching for sources of recycled material, as well as setting targets that reflect our long-term targets.

We have also extended this work and conducted baseline analysis for copper and steel (both stainless and low alloy steel) in our mechanical parts. Availability of recycled copper and steel is even lower than aluminum, and suppliers are only just starting to implement the requirement to have recycled content for these materials. The percentage of recycled material content for copper is 3% and for steel is 7% for low alloy and 13% for stainless.

We have also continued to increase the circularity of plastics used in our products by identifying projects where recycled plastics may be used. In 2023, Fixed Networks started shipping a second customized optical network terminal (ONT) design that uses 60% post-consumer recycled plastic in its housing. In addition, a new ONT was developed where a housing with 85% recycled plastic content is available as an option for customers. Meanwhile, Mobile Networks started shipping samples of the new Habrok radio that contains 50% post-consumer recyclate in the housing parts.

43%

We estimate that 43% of over 10,000 tons of cast aluminum parts used in Nokia products in 2023 have recycled content in them.

Extended Producer Responsibility (EPR)

Compliance with relevant environmental regulations is an important part of our environmental policy. Extended Producer Responsibility (EPR) regulatory programs strive to decrease the environmental impact of covered products by making the manufacturer responsible for the entire life cycle of the product, especially end-of-life (EOL) management through product takeback.

As EPR regulations evolve globally, we have continued our work on increasing product value recovery at end of life. Based on the Recycling and Reuse Metric that we pioneered with the iNEMI organization, we are now better able to evaluate new product designs with an eye towards improving materials choice, ease of parts and materials liberation, and available recovery technology in countries where the products are sold.

Sustainable product design

Our Design for Environment approach helps to ensure we create technologies that incorporate environmentally sustainable principles. Life cycle thinking is a key component of this approach. It helps us reduce our products’ lifetime environmental impact by improving material and energy efficiency. It also enables compliance with both regulatory and our own requirements.

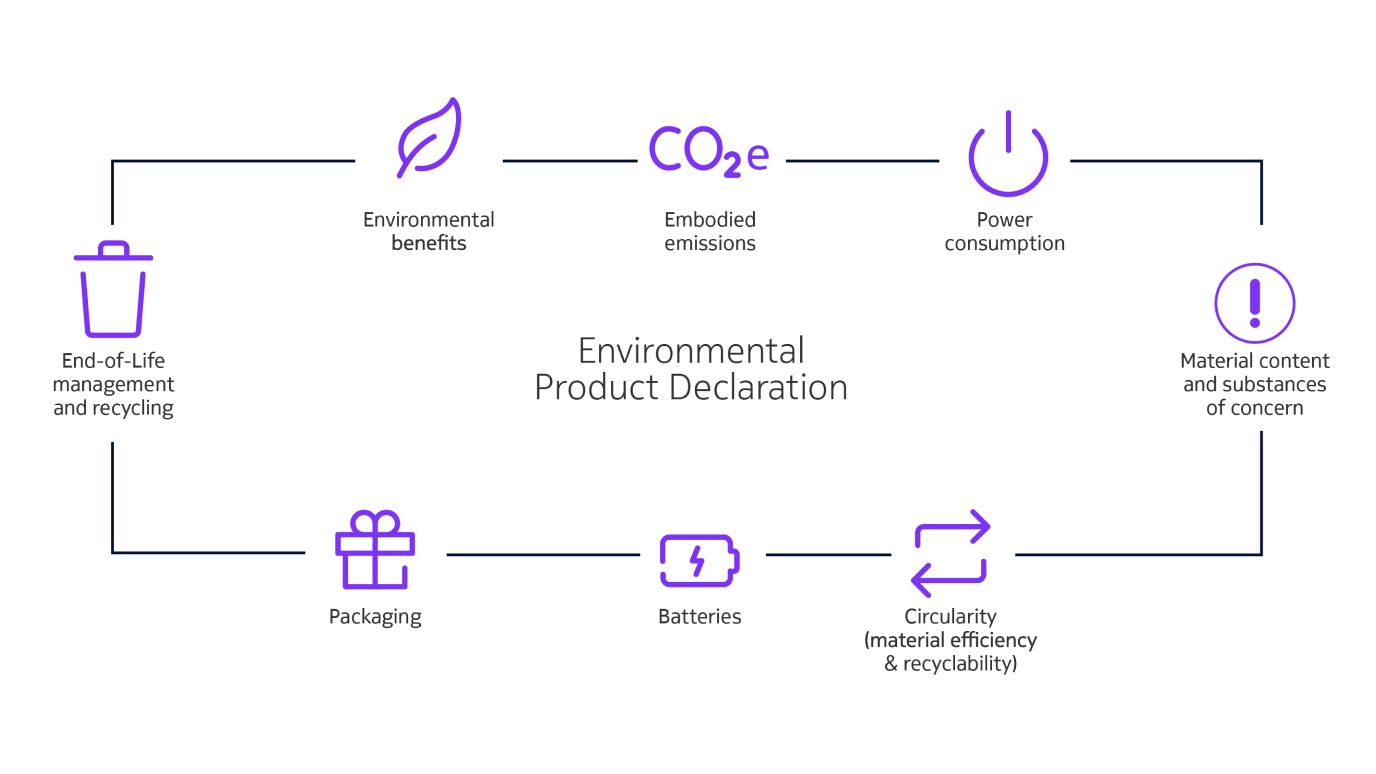

We provide an environmental product declaration (EPD) to our customers for the majority of our products. The EPD details environmental data for our products, including material composition, embodied emissions, power consumption and recycling instructions.

When looking at our products’ environmental impact calculated with life cycle assessment (LCA), the energy consumption during the product’s use stage forms the greatest part. We provide an EPD in both product embodied emissions (raw material acquisition, production, installation, maintenance, end-of-life treatment, and distribution and transport for each stage) and also product power consumption. The LCAs performed on our products follow the ITU-T L.1410 standard and the ISO 14040/14044 standards.

To help address this use stage energy consumption, our Design for Environment program supports product development teams by setting requirements and evaluating energy-saving features with each new product introduction. In 2023 we worked jointly within the International Electronics Manufacturing Initiative (iNEMI) to initiate a new round of updates for life cycle environmental impact data for key component categories used in our products – printed circuit boards, semiconductor devices and commodity materials such as metals and plastics. The intent is to have more contemporary datasets included to assess our products’ carbon footprint more accurately during their development (more information on this project and its call for participants can be found here.

Our Design for Environment program covers more than product hardware – it also includes the software designed to operate the hardware. Our software methodology documentation aims to help software developers significantly reduce the amount of energy used by network equipment by having them consider how their software code affects equipment energy use. To evaluate the resource efficiency and energy efficiency of the virtualization of network functions, our software developers employ the Resource Efficiency Rating (RER) and Energy Efficiency Rating (EER) metrics as defined in ETSI standard ES 203 539.

In 2023 we began collaboration with the Consortium for IT Software Quality (CISQ) that has evolved into a comprehensive standard measure, particularly in the form of an Automated Source Code Resource Sustainability Measure (ASCRSM). This new measure aims to address weaknesses with substantial impacts on resource usage, contributing to a more sustainable and efficient approach to software implementation.

Materials and restricted substances

Global legislation or regulations ban or restrict several substances considered hazardous to humans and/or the environment. In the design phase we ensure these substances are not present in our products, components and materials. Future customer and legal requirements may also influence product development choices made today.

Our products, including original equipment manufacturer (OEM) product parts, modules and components, must meet the requirements stated in the Nokia Substance List (NSL). In 2023 we again reviewed and published our NSL with minor changes to the requirements. The current list can be found here.

Suppliers must provide us with a list of any EU Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) candidate substance of very high concern present in a product. Furthermore, products, parts, modules and components must not contain any substance listed on the NSL as “to be avoided,” as far as is technically and economically possible. We aim to comply globally with all applicable substance requirements from environmental laws and regulations, such as the EU RoHS Directive (2011/65/EU), WEEE Directive (2012/19/EU) and REACH Regulation ((EC) 1907/2006). For more information on REACH, please see Nokia’s REACH Declaration.

In view of the increasing concerns regarding the very high persistence of per- and polyfluoroalkyl substances (PFASs), a thorough assessment was done across Nokia’s business groups and supply chain to identify where PFASs are used and understand what applications should be prioritized for research into substitution. In December 2023 we decided to list PFASs as “To Be Avoided” in the 2024 edition of the Nokia Substance List.

We globally restrict the use of ozone-depleting substances in products and packaging as well as in supplier processes per the requirements of EU Regulation (EC) No. 1005/2009 on Ozone-Depleting Substances, which implements the Montreal Protocol into EU legislation.

In 2023, we refreshed the material content data with supplier responses on NSL compliance, use of RoHS exemptions and presence of REACH Substances of Very High Concern (SVHCs) after distributing the updated NSL. The data is subsequently reviewed and stored in a dedicated database enabling us to review the impact of changing substance requirements on our current and future products.

Material efficiency innovation

Material efficiency includes designing products that use fewer materials and less energy while having increased throughput capacity and functionality. This material efficiency is exemplified in our Mobile Networks products. With our ReefShark System-on-Chip (SoC), the newest generation of mMIMO has higher energy efficiency and a significant reduction in materials compared to the previous generation. New chipset designs can provide a trio of benefits in power efficiency, materials reduction and capacity increase.

Product materials breakdown

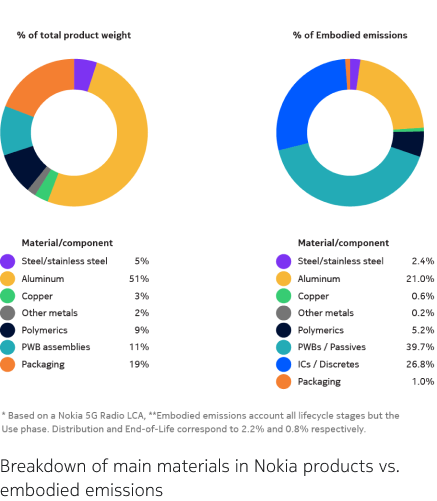

Our products are composed predominantly of metals, constituting around 80% of the total weight in most products. Aluminum is the most significant metal, and it is used in sheet metal for cabinets and chassis, and in castings for heat sinks. Steel, stainless steel and copper follow aluminum as the most relevant metals present in our products. Plastics only comprise less than 20% of our products by weight.

From an LCA perspective, it is not always the case that the heaviest material or component in our products has the biggest impact on climate change.

The graph above shows an example of the breakdown of a Nokia product (5G remote radio unit) into its weight and respective embodied emissions. In blue we show the percentage of weight respective to the total weight of the product. Similarly, in green we show the percentage of climate change respective to the total embodied emissions of this 5G radio.

This gives us the following environmental areas to focus on: material efficiency (including weight reduction, and leading to transport efficiency); higher percentage of recycled content for mechanical parts; and size minimization of integrated circuits (ICs) leading to reduced size of printed wiring boards (PWB) and a reduction in total passive components).

Product packaging

We have focused on reducing and eliminating plastics from our product packaging. In fact, we have explored alternative ways of using cardboard to make shock-absorbing elements and thus replace the traditional plastic foams. This has successfully been implemented in several Fixed Networks products in 2023. Mobile Networks is expanding its use of fiber-based cushions in the packaging of some products.

The plan for existing solutions is to initially replace plastic foam packaging in high-volume products. Additionally, we are focusing on the shift from linear to circular packaging designs and sourcing to make our packaging 100% recyclable and increase the use of recycled plastic content.

Such steps promote the sustainability of our packaging (increasing material circularity, reducing our CO2 footprint and limiting resource depletion) and bring more attention to waste reduction (assigning value to waste material incentivizes innovations in plastic and recycling technology).

There are several aspects of these new packaging solutions that differ from the standard solution. The first is easier recycling for the customer – the packaging can be easily flattened and the use of one single material saves time during recycling and helps avoid any contaminants. The second is improved sustainability – reduction of oil-based materials in the packaging, less microplastics in the ocean and avoidance of plastic taxation. In addition to customer recognitions, we have won several prestigious awards (iF Design Awards and Red Dot Design Award) for our sustainable packaging design and demonstrating peer recognition.