Leading management consultancy says Nokia autonomous drone service solves warehouse inventory challenges

The number one priority of the warehousing and logistics industry today is finding effective solutions for inventory visibility. And the most viable answer to this need has emerged in the form of autonomous drones.

That’s the main conclusion of a recently released study that the global management consultancy company Roland Berger conducted for Nokia.

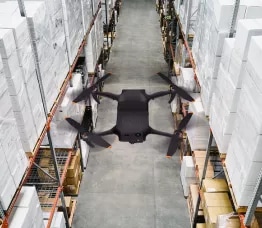

Into this void steps Nokia’s groundbreaking Autonomous Inventory Monitoring Service (AIMS), whose autonomous drones seamlessly fly though warehouses, scan inventory and constantly keep managers up to date with the true location of all the products on their shelves.

The culmination of years of Nokia Bell Labs research, AIMS marks the fusion of AI-enabled drone-based hardware, camera-based indoor localization, data analytics and computer vision. The result is improved accuracy and efficiency at lower costs for warehouse operators.

Roland Berger conducted a survey of industry executives and found that attracting, retaining and accuracy of human labor is one of the biggest pain points for warehouse managers. The study found that AIMS was particularly valuable in addressing major labor challenges like attracting and retaining staff and striking the right balance between accuracy and counting costs.

AIMS lessened these operational pain points by reducing count preparation activities, eliminating inefficiencies, and ensuring frequent counts at no incremental cost.

Equipped with advanced computer-vision-based scanning technology, drones can efficiently scan inventory at any time, including in areas not accessible by humans and not in direct line of sight. This automation looks to transform warehouse productivity and efficiency by eliminating the need for employees to engage in long hours of simple and repetitive tasks, thus leading to improved worker retention, health and safety.

The study showcased its conclusions through the example of a midsize warehouse of approximately 200,000 square feet with an inventory value of $25 million. The Nokia AIMS solution produced indicative yearly savings of up to $273,000. This included a direct labor cost savings of $125,000, savings in stock inaccuracies of $138,000 and savings in equipment use of $10,000. Since every warehouse operation is different, benefits can naturally vary between them.

Additionally, higher inventory accuracy and visibility can also translate into reduced needs for inventory buffers on hand and better turnover of inventory due to increased availability of products. Additional savings are also achieved from eliminating warehouse downtime for inventory counts. Emergency deliveries and second shipments can be significantly reduced and utilization rate of pallet space increased, leading to better customer satisfaction overall.

Another observation was the relationship between the cost of cycle counting and accuracy. Warehouses would generally spend more on cycle counting labor to achieve higher levels of accuracy (especially when contractually obligated to provide high levels of inventory accuracy) or would have lower inventory accuracy levels. The higher the accuracy, the higher the labor costs, and vice versa.

AIMS endeavors to provide customers with both the benefits of high levels of accuracy and a lower or similar cost to that of human workers.

It all adds up to a 30 percent or higher return on investment that could upend the warehouse industry.

The American wholesale distribution company Graybar has already deployed this novel solution in its warehouses and is seeing significant value and efficiencies from using AIMS.

“Very few technologies can simultaneously boost performance while reducing costs, but we believe AIMS can deliver both,” said Mark Hirst, Graybar’s VP Technology.

AIMS looks to provide an improvement on inventory management costs and efficiencies by at least seven times over – and solve the potential peril of human safety issues in large-scale warehouses.

In doing so it looks to reframe the long-standing industrial quandary of having to choose between investing heavily in high-cost manpower to manage inventory or accepting the inevitable costs of “shrinkage” where products are lost or misplaced in large warehouses.

To learn more about Nokia AIMS and how you can achieve warehouse clarity, please reach out to Paul Heitlinger at paul.heitlinger@nokia.com