The key to unlocking $1.8 billion in logistics revenue in Europe

According to ABI Research, the logistics market is projected to lose more than $1.8 billion in revenue in 2024 due to poor network connectivity.[1]

Why? Because the current, one-size-fits-all wireless connectivity layer is not well suited to connect applications that drive the high levels of automation these organizations have widely adopted.

The root cause of this mismatch is found in the fast pace of change in our shopping behaviour over the last five years or so. We’ve all shifted a great deal of our spending from highstreet shopping to online shopping and the comfort of our sofa. Covid hugely accelerated this trend, taking e-commerce sales to new highs in countries across Europe.

Online sales in Europe, particularly in top markets like the UK, Germany and France, have seen significant growth since 2017 and are projected to continue rising, with the share of online sales more than doubling from 9.9 percent in 2017 to an anticipated 21 percent by 2028.[2]

The last mile to consumers is critically important

Consumer expectations have also changed and people now want packages delivered within 24 hours. Large, online marketplaces such as Amazon have redefined delivery speeds and raised the bar for online retailers and businesses alike.

In response to this trend, retail and logistics companies are taking major actions to ensure high levels of shopper expectations can be met. In some cases, retail units in city centers are being stripped and transformed into last-mile micro-fulfilment centers (MFCs) that are located closer to consumers. In other cases, greenfield warehouses are being built in rapid succession.

Wi-Fi can’t keep up with increasingly high levels of automation

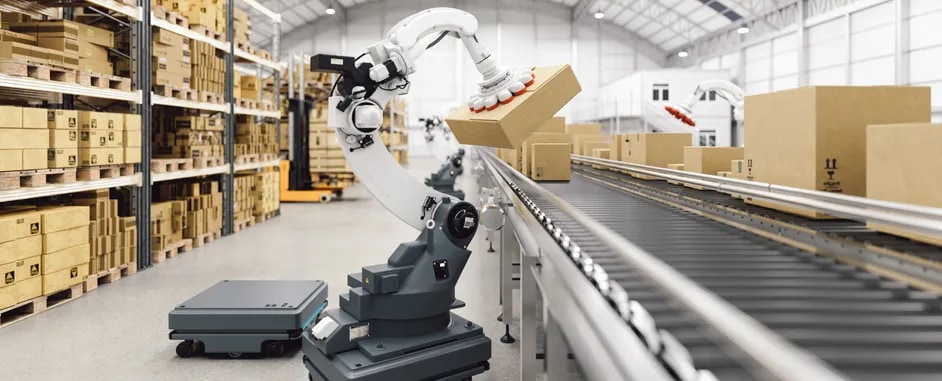

These new MFCs are equipped with the highest levels of automation technologies and implement the latest use cases to ensure fulfilment is fully automated.

High-tech use cases such as automated guided vehicles (AGVs) or Autonomous Mobile Robots (AMRs), asset tracking and drone-based operations are being adopted at huge scale, but are often connected to Wi-Fi networks, which can create connectivity and performance issues.

One of the major issues is that mobile robots struggle to handover to the next Wi-Fi access point fast enough, so they stop, slowing the delivery process and productivity. In addition, outdoor loading bays lose connectivity, and asset tracking through the supply chain becomes a challenge. Unfortunately, Wi-Fi alone cannot keep up with the rapid deployments of these high automation use cases.

However, there is a proven solution to the Wi-Fi challenges in MFCs and warehouses.

5G private wireless is proven to deliver business benefits

To ensure connectivity issues becomes a problem of the past, MFCs and warehouses need a mission-critical high-bandwidth and low-latency technology foundation based on 5G wireless connectivity.

Wi-Fi will still be used for IT-based applications, but for operational technology (OT), MFC and warehouse operators must add a wireless technology layer that can handle the wide range of automation use cases currently being deployed. An on-premises compute solution can help to quickly deploy additional use cases.

One of our customers, a white goods manufacturer in Istanbul, saw a 25 percent increase in cycle time when they switched from a Wi-Fi network to a pervasive and reliable 5G private wireless network to connect their AGVs. We’ve also seen customers decrease their energy consumption and related costs by 20 percent because a 5G private wireless network requires fewer access points to connect automated vehicles and support other use cases.

MFCs can unlock double-digit year-over-year growth

To ensure MFCs and warehouses can deploy the 5G private wireless connectivity they need in a cost-effective way, Nokia has developed a lightweight version of its popular Digital Automation Cloud (DAC) private wireless connectivity platform.

The Nokia DAC Private Wireless (PW) Compact provides flawless coverage and nearly unlimited bandwidth for low-latency use cases, including video analytics-based drones, autonomous mobile robots (AMRs) and asset tracking. It empowers highly automated fulfilment centers to work flawlessly around the clock and benefit from the additional revenue that automation use cases enable.

The ABI Research chart below illustrates how private cellular networks contribute to annual revenues in the logistics market when connecting key automation use cases.

Nokia DAC PW Compact can be installed as easily as Wi-Fi, and we offer a three-year subscription service. Best of all, total cost of ownership (TCO) for the DAC PW Compact is 20 percent lower than that of Wi-Fi, so there are only benefits for organizations that adopt it. This cost efficiency is perhaps the biggest secret or misconception in the industry when it comes to 5G private wireless.

We can also provide a solution where 5G and Wi-Fi run on one platform, so IT and OT can work together to connect the right application to the right technology.

Step up to 5G private wireless

To learn more about the Nokia DAC PW Compact and how it can help your MFC or warehouse automate and accelerate business to unlock revenue, visit our webpage or contact us so we can connect you to the right partner in your region. Today, Nokia DAC PW Compact is available in North America and Europe.

References

[1] Contribution of Private Cellular to Annual Revenues - Logistics Europe: 2022-2030.

[2] Statista Market Insights, October 2023.