With a new inventory counting feature, Nokia AIMS offers a complete automated solution

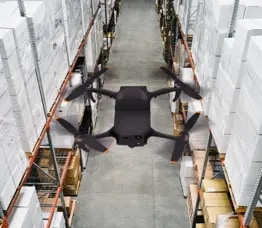

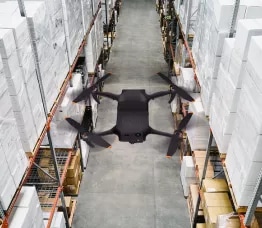

Nokia’s groundbreaking Autonomous Industrial Monitoring Service (AIMS) has transformed the traditional inventory counting process. Its autonomous drones can seamlessly fly though warehouses, scan inventory and constantly keep managers up to date on the true location of inventory in warehouses.

It’s already been deployed by the American wholesale distribution company Graybar and the result has been improved accuracy and efficiency at lower costs. In fact, a study the global management consultancy company Roland Berger conducted for Nokia found that these autonomous drones offer the most effective solution for inventory visibility.

But while AIMS has been able to track inventory, it hasn’t yet been able to count all of it. Until now. With the launch of the AIMS new automated inventory counting feature, customers will be able to have an accurate count of all visible boxes or items in an inventory location on a rack shelf – even those stacked multiple rows deep. If it is visible from an aisle, AIMS will be able to count it.

This feature is already available to new and existing customers. It marks the next generation of up-to-date inventory analytics that can reduce low-value manual labor and transform productivity and efficiency.

The AIMS inventory counting feature is just the latest innovation available to Nokia AIMS customers and even more is expected. Our engineers continue to work alongside Nokia Bell Labs researchers to develop new innovative and useful features for the warehouse industry.

AIMS brings together barcode scanning and drone autonomy technology into one seamless warehouse management service. As such, it transforms the traditional inventory cycle counting process with autonomous drones and cloud analytics software. Once fully operational, it will make the high labor cost, human error and occupational hazard of workers manually scanning boxes throughout warehouses into a thing of the past.

Our initial testing has shown that this new feature can achieve greater than 90 percent accuracy so customers can now use AIMS to count the inventory on their shelves and find out if and where it matches with their records.

This is the first function of its kind in the industry - no other company can provide automated and accurate inventory counts. With drones using multiple images from each location to build a multi-angle picture, it offers the prospect of truly upending the warehouse inventory counting industry.

AIMS can be used to improve service levels for warehouse operators, distributors, third party logistics, equipment manufacturers, retail and grocers. A Nokia AIMS drone can complete cycle counts approximately seven to ten times faster than human workers, or around 300 inventory locations per hour. And it can provide customers with a 40 percent or greater return on investment.

In doing so, AIMS looks to reframe the long-standing industrial quandary of having to choose between investing heavily in high-cost manpower to manage inventory or accepting the inevitable costs of “shrinkage” where products are lost or misplaced in large warehouses.

Warehouse shrinkage can account for 3-5 percent of a company’s revenue and 25 percent of shrinkage is due to administrative errors. The new inventory counting capability adds to AIMS’ current features of finding misplaced and lost inventory, as well as empty bin detection.

Taken together, it all adds up to a competitive edge that keeps customers at the forefront of automation. It also gives them peace of mind. Our drones are designed to work beyond typical working hours, freeing up human workers to focus of the high-value tasks that make the greatest difference for their business.

To learn more about Nokia AIMS and how you can achieve warehouse clarity, please reach out to Paul Heitlinger at paul.heitlinger@nokia.com